Gen5 Waterless Cooling and Flux Separation System – Heated Cooling Module in 1st Cooling Zone for Controlling Cooling Slope – Enhanced Waterless Cooling Modules for Low Product Exit Temperature.

Complete Computer Control System including:

- Flat Panel Color Monitor & Keyboard Support Arm

- ECD CPK & SPC data and alarm logging with timed download or printout capability

- 5 Thermocouple “Real Time” profiling

- Complete KIC & ECD Profiling & Storage Software including the following features:

- Profile Storage/Overlay Software including the following features:

- Profile Graph Storage of up to 500 graphs

- Profile graph overlay of “benchmark” profile with current profile

- Profile graph phase shifting to align two graphs

- Moveable slope window providing average slope over given portion of graph

- 6 color graphics to distinguish between graphs

Benefits of the Mark V series SMT reflow oven system

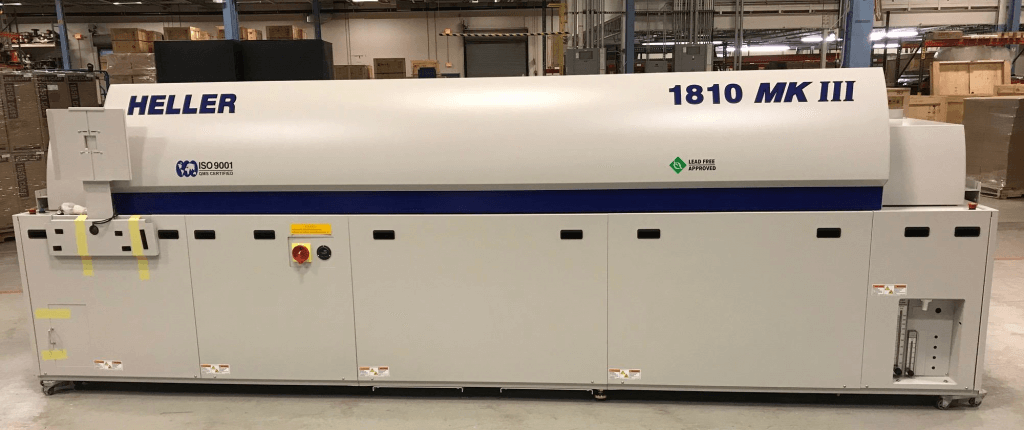

Reflow Oven Specifications:

- Make: Heller

- Model: 1810 MKV

- Vintage: 2014

- Process Flow: Left to Right

- Hours: 365 …Like New!

- Software: Windows 7

- 2 Internal Cooling Modules with 30” of Cooling

- 20 Independent Temperature Controlled 350°C Balanced Flow “Lead Free” Heating Zones

- Nitrogen On/Off Capability (Computer Controlled)

- Oxygen PPM Monitoring System

- Spike Zone Design for minimal liquidous time

Enhanced Low Height Heater Modules

Enhanced flow heater modules with 40% larger impellar, blanket the PCB with heat for the lowest delta Ts on the toughest boards! Additionally, the Uniform Gas Management system eliminates net flow which results in nitrogen consumption reductions of up to 40%!

New Low Height Top Shell

New low height top shell reflow oven provides much easier access for oven operators. All skins have double insulation to save up to 10-15% in energy losts. PID temperature control to ensure zone temperature stability to +/- 1°C

Signal Light Tower to indicate system status 4 moveable casters for easy relocation around shop floor Power controlled Clamshell Hood Lift Single exhaust port for easy facilitation 480V, 60 HZ, 3 phase, 100 AMPS per phase Left to Right Process Width

New low height top shell reflow oven provides much easier access for oven operators. All skins have double insulation to save up to 10-15% in energy losts. PID temperature control to ensure zone temperature stability to +/- 1°C

Signal Light Tower to indicate system status 4 moveable casters for easy relocation around shop floor Power controlled Clamshell Hood Lift Single exhaust port for easy facilitation 480V, 60 HZ, 3 phase, 100 AMPS per phase Left to Right Process Width

Revolutionary Flux Management System

Our revolutionary flux collection system traps the flux in collection jars that can be easily removed and replaced while the oven is running – saving time consuming P.M. The new flux filtration box also has no risk of flux clogging for a longer term P.M. interval. Additionally, our proprietary Flux-Free Grill system limits the flux residue on the cooling grills giving the Heller system the highest production yields of any oven!

Programmable Cooling

The new Big Flat Coil Cooling module provides cool rates of >3ºC/sec. That rate meets even the most demanding lead-free profile requirements. Heller can also easily achieve slow cooling rate required by the flip chip process. Our unique design uses a 10-inch (250 mm) long heater module to provide more modules within the same heating length which means more process control and reduced liquid times.

Energy Management Software

Reflow Oven CPK

Heller provides dynamic 3 tiered system (Tier 1: Oven CPK, Tier 2 Process CPK, Tier 3 Product Traceability) enables customer to quickly improve product quality and yield while reducing costs. And the additional benefits of automatic record keeping and recall provide customers with the peace of mind that all process parameters are under control and within spec.